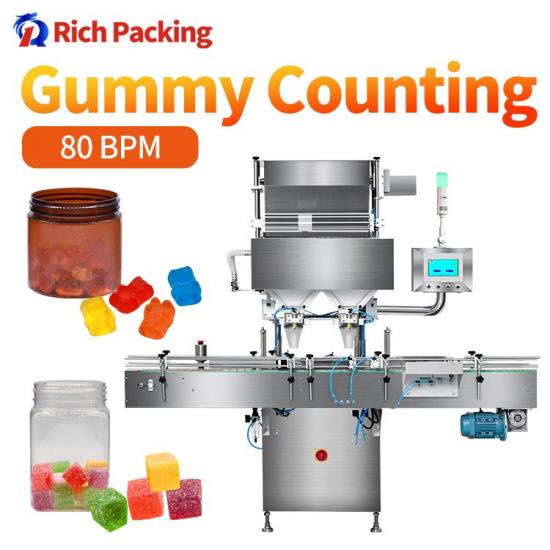

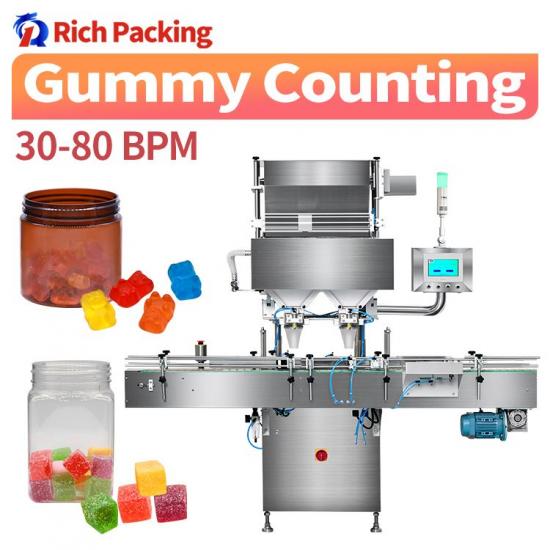

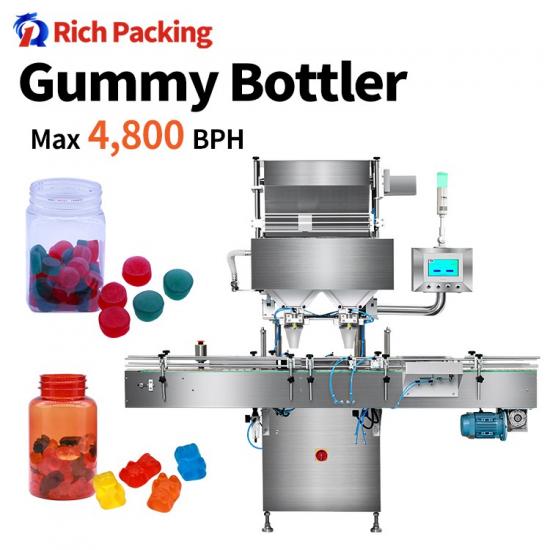

Fully Automatic Gummy Counting Machine

At present, there is a strong demand for fast electronic counting in fields such as the gummy, candy, pharmaceutical bottling industry and the food packaging industry worldwide. The high-speed counting machine RQ-DSL-16R developed and produced by our company is a set of high-end upgraded material counting equipment of RICH PACKING.

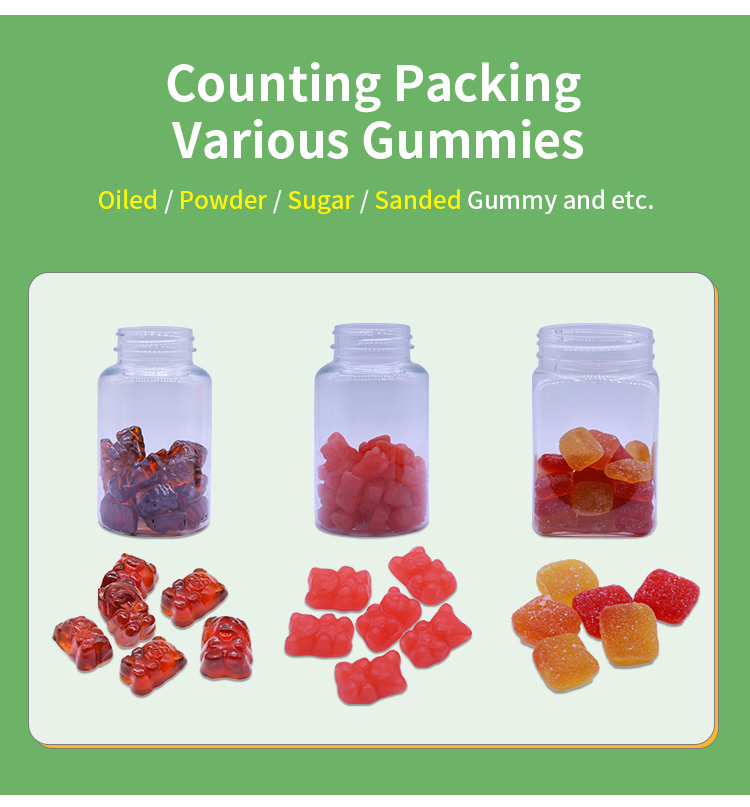

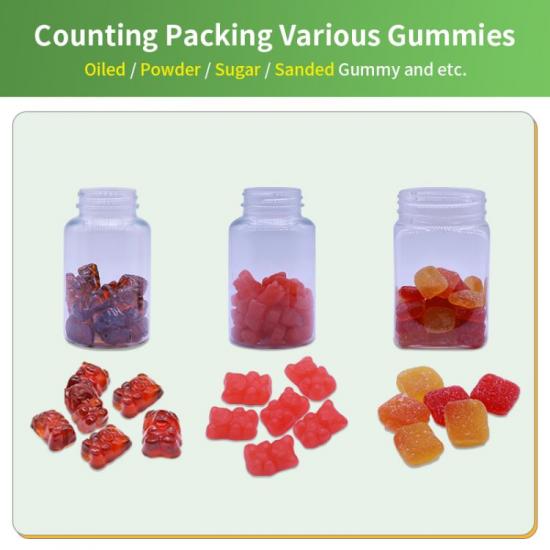

The counting objects faced by the DLSL-16R gummy counting machine include gummies medicinal capsules in the packaging field, edible candy and chewing gum, small hardware products, etc., and filling into bottles.

*** Applications

*** Technical parameter

| Name | Automatic gumy candy counting machine DSL-16R |

|

Production capacity |

50-80 bottles/min |

|

Net weight of machine |

907Kg |

|

Counting Precision |

>99.97% |

|

Power |

380/220V 50Hz |

|

Total power |

2.55KW |

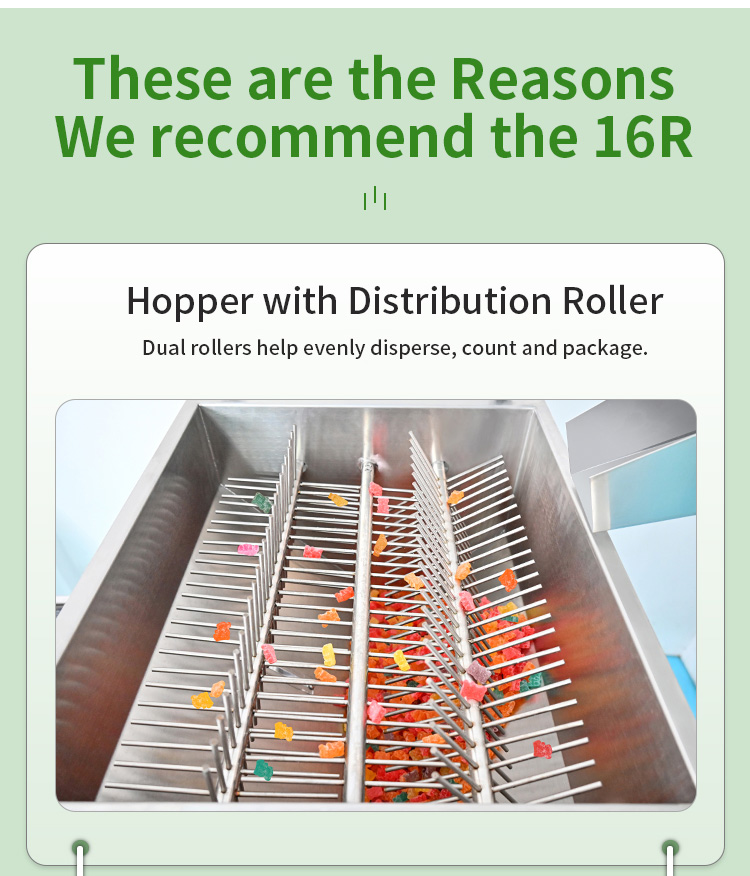

*** DSL-16R’s Hopper with Distribution Roller

Dual rollers help evenly disperse, count and package.

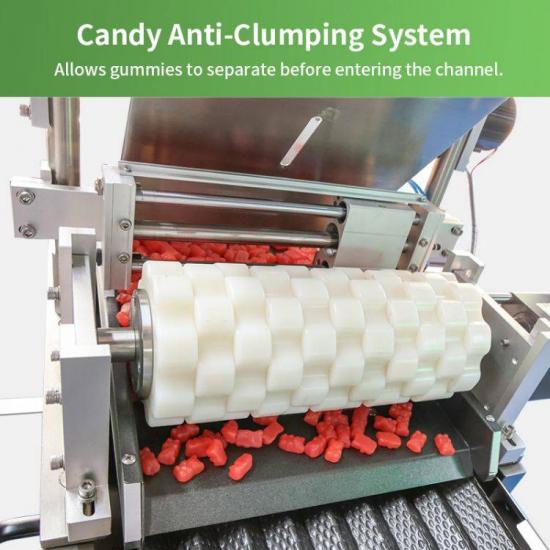

*** The New Cylinder Control Slide in DSL-16R.

Allows gummies to separate before entering the channel.

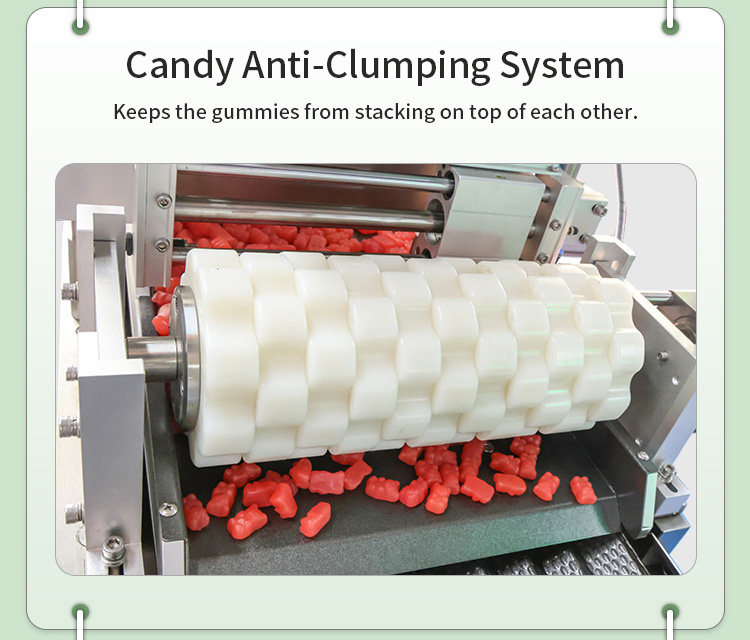

*** The Candy Anti-Clumping System in 16R.

Keeps the gummies from stacking on top of each other.

*** What Makes Us Different From Others

***

The DSL-16R counting machine can be combined with other supporting equipment to form a high-speed counting and filling line. These equipments can be customized by customers according to their needs. These equipments include high-speed bottle sorting machines, electronic intelligent gummy counting machines, and material desiccant filling. Machine, bottle mouth aluminum foil sealing machine, bottle cap screw cap sealing machine, bottle labeling machine, etc.

After the supporting machine of the counting machine described above is connected through the conveyor belt, the synchronous operation can be realized by connecting the PLC system through the debugging of the technicians, thus ensuring the stability of the counting line for long-term operation.

The core equipment of the counting production line is the DSL-16R electronic gummy counting machine with modular design, which can provide quick adjustment functions and the purpose of independent use of two counting channels. The entire counting production line can realize simple and fast assembly and separation. The outer frame of the whole 16H pellet counter is made of high-quality 304 stainless steel, and the contact part of the 16R and counted materials is made of 316 stainless steel. After grinding and polishing, the machine fully meets GMP requirements.

IPv6 network supported

IPv6 network supported