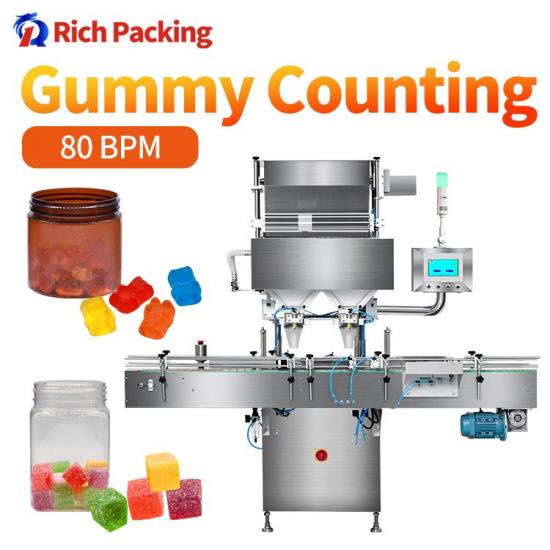

DSL Oil Coated Candy Counting Machine By Rich Packing

The counting machine is widely used in the pharmaceutical and food industries. It is one of the key equipment in the production and packaging line of bulk medicine and candy bottles. At present, there are mainly photoelectric counting machines in the target market. The effect task principle implements the packaging equipment of automatic counting, which can handle various shapes and different specifications. RICH PACKING candy special counting machine has the logic of adopting high-speed photoelectric counting and whole stack counting. Its functions are high-speed, accurate in counting and easy in structure.

The special counting machine for candy breaks the traditional method. The flow of goods is conveyed by the material tray in a single-layer tiled form, and there is no need to divide it into a single channel. When the whole pile falls, it passes through the imaging area and counts. The latest generation of soft candy counting method does not need to make up the difference of the counted items. The item pile passes through a logical dispatcher, and the computer monitors the distribution pattern of the item pile when it enters the dispatcher, and allocates the target number by logical calculation method.

Photoelectric counting candy method, remote imaging, not affected by dust; can distinguish fragments, broken particles, and can reject materials in small piles to prevent overflow of production capacity; items do not need to be divided into single-lane channels and do not need to leave, single-layer tray feeding , Integrate the channel, greatly increase the feeding density and production capacity.

*** Technical parameter

|

Model |

RQ-DSL-16R |

|

vibration groove tracks |

16 lane |

|

Production capacity |

200,000 ~ 360,000 grains/h |

|

accuracy rate |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

Applicable target |

Tablet:Φ3~25 mm ,pill:Φ3~20 mm, |

|

Applicable bottle type |

Φ25~75 mm round and square bottle, height ≤240 mm |

|

voltage |

AC380V 3P 50 / 60HZ |

|

power |

2.2 KW |

|

pressure |

0.4~ 0.6 Mpa |

|

Air consumption |

120 L/min |

|

Hopper capacity |

45 L |

|

weight |

650 kg |

|

Outline dim.(mm) |

1200×1550×1750 mm |

*** Configuration List

|

No. |

Item |

Specification |

Qty. |

Manufacturer |

|

1 |

Count Photoelectric Sensor (Receive) |

N24.5R |

16 |

Lattine |

|

2 |

Count Photoelectric Sensor (Emit) |

N24.5E |

16 |

Lattine |

|

3 |

Valve Group |

M4SB10-M5-6 |

2 |

Japan CKD |

|

4 |

Filtrate Regulator |

FR500 |

1 |

Taiwan SHAKO |

|

5 |

PLC Group |

FP∑-C32TH FPO-E16YT |

1 |

Japan Panasonic |

|

6 |

Touch Screen |

GE4408W |

1 |

Japan Pro-face |

|

7 |

Cable Diffuse Sensor |

QS18VN6DB |

3 |

USA.BANNER |

|

8 |

AC Contactor |

GMC-9 |

1 |

Korea LG |

|

9 |

DC Contactor |

GMD-9 |

3 |

Korea LG |

|

10 |

Thermal Overlood Relay |

GTH-22/3 |

1 |

Korea LG |

|

11 |

Count Cylinder |

SCPS2-1030 |

16 |

Japan CKD |

|

12 |

Position Cylinder |

SDA20-10 |

4 |

AIRTAC |

|

13 |

Control Box |

131200000 |

1 |

Germany MECANO |

|

14 |

Directive Signal Light |

AL6M-P |

3 |

Japan IDEC |

|

15 |

Button Switch |

ABW310EG |

1 |

Japan IDEC |

IPv6 network supported

IPv6 network supported